LUBRON AQ

LUBRON AQ bearings are constructed of high strength bronze alloys permanently embedded with PTFE solid lubricants, and are unequaled for toughness and durability. Suitable for long-term immersion in flowing water, LUBRON AQ bearings are the proven choice for offshore/marine, hydro power generation and dam gate applications.

Bearing Types:

Sleeve Bearings

Flange Bearings

Thrust Bearings

Spherical Plain Bearings

Expansion Bearing Plates

Radial Bearing Plates

Spherical Bearing Plates

Application Types:

Aerospace & Defense

Hydro Power & Water Control

Industrial

Infrastructure

Offshore/Marine

LUBRON AQ self-lubricating bearings are designed to accommodate high loads for long lengths of dwell in both wet and dry applications where environmental conditions are often severe and external lubrication is impractical. LUBRON AQ bearings are constructed of corrosion resistant bearing alloys and permanent solid lubricants specifically developed for underwater use. LUBRON AQ bearings provide dependable performance and long service life, require no supplementary lubrication, and are completely maintenance-free.

PERMANENTLY LUBRICATED & MAINTENANCE-FREE

LUBRON AQ self-lubricating bearings feature a proprietary PTFE-filled solid lubricant embedded in a cast bronze backing. Widely used in hydro dam gate and water control applications, LUBRON AQ bearings require no maintenance and provide superior performance throughout long service life. LUBRON AQ30 and AQ100 lubricants, specially formulated for underwater immersion, compliment a wide selection of solid "oilless" lubricants available from Lubron Bearings Systems. LUBRON AQ lubricating compounds are integrally molded and compressed into recesses provided for permanent containment of the lubricant. Drilled circular recesses are provided over a minimum 30% of the entire bearing surface area in uniform, geometric and overlapping patterns to assure optimum lubricating coverage. LUBRON AQ30 lubricants are machined flush with the bearing surface. LUBRON AQ100 lubricated bearing surfaces are applied with an additional lubricating film up to .040 inches (1 mm) thick over 100% of the bearing area, eliminating asperity contact for maximum resistance to wear and optimum performance. LUBRON AQ100 is particularly suitable for bearings subject to galvanic attack and severe water velocity, the predominant factors affecting corrosion rates. Adequate lubrication is the single most important factor for successful operation of a bearing, especially for high strength bearing alloys that require continuous lubrication to prevent seizing, scoring and galling. LUBRON AQ self-lubricating bearings are effective in applications where relative motion is not sufficient to promote circulation of oil or grease. LUBRON AQ solid lubricants provide a permanent lubricating film separating the bearing components, with the capacity to reduce friction and resist wear independent of an external lubricant.

HIGH LOAD CAPACITY & LOW FRICTION

LUBRON AQ bearings have excellent resistance to impact and shock loads, and can tolerate a high degree of shaft misalignment. Ideally suited for applications where loads are too great to permit the use of oils or grease, LUBRON AQ bearings are capable of continous operation up to 8,000 psi (562 kg/cm2) and short-term operation up to 15,000 psi (1055 kg/cm2). LUBRON AQ bearings exhibit low friction at high loads, and low friction at low speeds, which makes them ideal for oscillating and reciprocating applications.

CORROSION RESISTANT

LUBRON AQ bearings are not affected by most harsh or corrosive environments. Constructed of chemically inert lubricants and corrosion resistant bronze alloys, LUBRON AQ bearings are designed to resist galvanic action, pitting, cavitation, erosion and biofouling. Aluminum bronze and manganese bronze, which offer excellent corrosion resistance and high mechanical strength, are most frequently utilized for fresh and sea water applications.

SUPERIOR PERFORMANCE & LONG SERVICE LIFE

LUBRON AQ bearings have proven their ability to perform in rigorous operating conditions. Capable of withstanding icing, silt, and erosion from severe water flow, LUBRON AQ’s built-in wear resistant solid lubricants, securely bonded to high strength bronze alloys, combine to provide superior performance and exceptional endurance and long service life.

MAXIMUM SAFETY & RELIABILITY

The common cause of bearing failure is inadequate lubrication resulting in metal-to-metal contact, which greatly increases friction and often leads to seizure. LUBRON AQ bearings are designed to avoid bearing failure and premature wear. By offering a unique combination of properties and capabilities, LUBRON AQ bearings provide reliable and continuous lubrication of the bearing surface.

APPLICATIONS

LUBRON AQ bearings are utilized in a variety of hydro dam and water control applications subject to medium-to-heavy loads and slow-to-medium speeds. LUBRON AQ’s versatile properties provide maximum bearing life and trouble-free operation in both immersed and dry environments.

Combining the low friction of PTFE with the rigidity of high strength bronze alloys, LUBRON AQ bearings are capable of satisfying the most demanding requirements.

Applications include:

radial gates

jet low gates

intake gates

tainter gates

draft tube gates

slide gates

sector gates

roller gates

crest gates

miter gates

sluice gates

sheaves

navigation locks

flap gates

fish ladders

trashracks

bulkheads

penstocks

weirs

stoplog guides

roller & hoisting chains

CONSTRUCTION

LUBRON AQ self-lubricating bearings feature a combination of properties and capabilities unsurpassed by other maintenance-free bearings. The key to LUBRON AQ’s superior performance is its unique structure, composition and method of manufacture.

LUBRON AQ30 and AQ100 bearings are comprised of a bronze substrate and a bronze-lubricant inner structure. The bronze substrate provides a high load carrying capacity with excellent dimensional and structural rigidity. The bronze-lubricant inner structure supplies a permanent reservoir of lubricant for continuous restoration of the low friction bearing surface.

Cast Bronze Alloys

Cast bronze alloys have been used for centuries in a broad spectrum of bearing applications. Other bearing materials have been unable to match their versatility. By alloying copper with other elements, the properties of bronze can be altered to suit the requirements of most any application. The choice of a bronze alloy for a particular application is determined by the desired physical, mechanical and metallurgical properties needed. For applications exposed to flowing water, corrosion resistance becomes a critical consideration. Corrosion associated with high water turbulence includes cavitations, erosion, and impingement attack. Pitting, galvanic, and crevice attack are other common forms of corrosion. The extent of corrosion attack depends on the bearing environment and alloy composition. Oxygen and chlorine content, conductivity, water velocity, temperature, salinity, and biofouling affect rates of corrosion. Tensile strength, yield strength, fatigue strength, hardness, and grain refinement influence the ability of an alloy to withstand corrosion.

A wide selection of corrosion resistant alloys are available for underwater applications. Manganese bronzes are used extensively in fresh water applications, especially where toughness and shock resistance are necessary. Tin bronzes, which offer high resistance to impingement corrosion, and leaded tin bronzes, which provide good embedability and tolerate greater shaft misalignment, are generally limited to low and moderate bearing loads. Aluminum bronzes, capable of much higher bearing loads, are widely used in both fresh water and marine applications. Because seawater is an excellent electrolyte, severe galvanic corrosion often occurs when two dissimilar metals are coupled together. Aluminum bronzes provide high resistance to galvanic action, as very minor potentials are generated between aluminum bronze and Monel, Inconel, nickel or stainless steel. Most aluminum bronzes offer good resistance to creep, biofouling, cavitations, impingement corrosion and chemical attack.

LUBRON AQ alloys are manufactured in strict compliance with ASTM and ISO material specifications. Some alloys receive supplementary heat treatment to enhance surface hardness and corrosion resistance. Centrifugal, continuous, sand, and forged castings are available, depending on the size and shape required.

Permanent Lubrication

LUBRON AQ lubricants are "graphite-free" and do not contain any ingredients which promote electrolysis. Graphite has a very noble potential of +0.25V which can lead to severe galvanic corrosion of copper alloys and stainless steels in saline waters. LUBRON AQ lubricants consist of PTFE (polytetrafluoroethylene) and epoxy resins, hardeners, metallic and fibrous fillers, specially compounded to achieve optimum bearing performance. Low friction properties are derived from the natural lubricity and high concentration of PTFE. Epoxy resins and hardeners provide superior adhesion, thermal stability, wear and chemical resistance. Reinforcing fillers are added to increase the lubricant’s resistance to deformation under load and distortion due to elevated temperatures.

LUBRON AQ lubricants are embedded into circular recesses provided for containment of the lubricant. Covering 30% to 40% of the bearing surface, these recesses securely anchor the lubricant and provide permanent reservoirs for restoring the bearing surface.

LUBRON AQ30 lubricants are machined flush with the bronze substrate surface. The lubricated surface is continuously replenished by relative movement between the bearing and mating surfaces.

LUBRON AQ100 bearings offer an additional lubricant film from .001 inch (.025 mm) up to 0.040 inch (1 mm) thick, providing a full and positive separation between the bearing and mating surface. For most applications, LUBRON AQ100 bearings provide longer wear life and lower coefficient of friction.

PERFORMANCE

LUBRON AQ bearings provide proven performance for demanding underwater applications. LUBRON AQ’s bronze alloy and solid lubricant construction offers the optimum choice for toughness, rigidity, and low coefficient of friction, dry or immersed.

Load Capacity

Load carrying capacity generally depends on the compressive strength of the bearing alloy and its permissible permanent set. For most applications, the recommended bearing loads listed in Table 1 will provide a safety factor of at least 3. LUBRON AQ bearings, which combine high strength alloys with tough, resilient lubricants, are designed to withstand heavy loads.

Coefficient of Friction

In low speed, high load applications, LUBRON AQ solid lubricants have a typical coefficient of friction between 0.02 to 0.10, depending on a variety of factors affecting performance. Type of environment, bearing load, velocity, temperature, finish and hardness of the mating surface all influence coefficient of friction.

Bearing Wear and Life

LUBRON AQ’s low friction and abrasion resistant properties help minimize wear and extend bearing life. Wear is a surface phenomenon that results in the gradual deterioration of contacting surfaces through friction. Friction is of less practical importance than the rate of wear, which is defined in terms of volumetric loss of material over time.

Volumetric wear is approximately proportional to the unit load multiplied by the distance traveled, and is generally expressed as follows:

W= KPVT

where W= wear depth, in (cm)

K= proportionally constant, in3-min/ft-lb-hr (cm3-min/m-kg-hr)

P= bearing pressure, psi (kg/cm2)

V=surface velocity, ft/min (m/min)

T=elapsed time, hr

K values for LUBRON AQ100 lubricated bearing surfaces have been derived from independent testing, and can be used to determine the amount of wear that will occur over a period of time. For most applications, a value of K-1.8 x10-9in3 -min/ft-lb-hr (2.2 x10-7 cm3-min/m-kg-hr) is appropriate.

In tests performed by independent laboratories, LUBRON AQ100 bearings have exhibited wear of less than .003 inches (.076 mm) for loads up to 6,000 psi (422 kg/cm2) and durations exceeding 250,000 cycles at 10° oscillations and 9 cycles per minute. These tests occurred without any degradation of the beairng or mating surfaces, and have demonstrated wear life 2 to 15 times longer than similar competitive bearings.

In actual applications, wear can be affected by a combination of many factors. By minimizing PV, deformation due to shaft misalignment, rotational vibration and excessive heat, LUBRON AQ bearings will achieve long service life.

DESIGN CRITERIA

The overall performance of LUBRON AQ bearings is directly influenced by a variety of operating factors which in particular include bearing load, speed, PV and type of movement. The following section describes the design criteria needed to properly specify a LUBRON AQ bearing. While specific criteria are not provided for every application, essential design considerations and guidelines are discussed in some detail. For unusual design problems, additional assistance will be provided.

Alloy Selection

Proper alloy selection is necessary to attain maximum resistance to wear and corrosion. Ideally, the bearing and its mating surface are always separated by the LUBRON AQ lubricant film. Over a long period of time, however, extreme wear of the lubricant may result in mating surface contact. Under these circumstances, the selection of the bearing alloy becomes particularly important. Table 1 is intended to aid the engineer in selecting a suitable alloy for the specific application under consideration. Physical and chemical properties, comparative specifications, recommended design loads and performance characteristics are provided for several bronze alloys most often used in fresh water and saltwater applications Other alloys are also available to satisfy special requirements.

TABLE 1

| Alloy No. | Generic Decription | ASTM Specification | Maximum Recommended Bearing Load | Maximum Recommended PV |

| 932 | High Leaded Tin Bronze | B584-C93200 | 1500 psi 10 N/mm2 |

24,000 psi-ft/min 50 N/mm2-m/min |

| 954 | Aluminum Bronze | B148-C95400 | 4000 psi 27.5 N/mm2 |

48,000 psi-ft/min 100 N/mm2-m/min |

| 955 | Nickel Aluminum Bronze | B148-C95500 | 6000 psi 41 N/mm2 |

72,000 psi-ft/min 150 N/mm2-m/min |

| 863 | Manganeze Bronze | B584-C86300 | 8000 psi 55 N/mm2 |

80,000 psi-ft/min 170 N/mm2-m/min |

Selection of a suitable alloy depends on a variety of factors, which include bearing load, velocity, type of movement, temperature, environment, shear strength, fatigue strength, deformability, compatibility, hardness differential, corrosion resistance, wear resistance, and cost. These factors should be evaluated with regard to all bearing system components to obtain long bearing life and maintenance-free operation.

BEARING PRESSURE

Bearing pressure (P) is defined as the total load applied on the supporting or projected area of the bearing, and is expressed as psi (punds per square inch), kg/cm2 or N/mm2.For uniformly loaded bearings, bearing pressure can be calculated as follows:

P = LOAD/PROJECTED AREA = LOAD/IDXLENGTH (brushings)

=LOAD/.0785X(OD2-ID2) (Thrust washers & flange thrust surfaces)

=LOAD/WIDTHXLENGTH (Plates)

Bearings should be sized to accommodate the total applied load without exceeding the maximum design load. Recommended maximum design loads are shown on Table 1, having been determined by dividing the yield strength of each alloy by an appropriate safety factor. In most cases, the safety factor is extremely high, and actual loads may occasionally exceed the design load with no detrimental effect on bearing life.

Velocity

Surface velocity of a bearing is expressed in surface feet per minute (SFM) or meters per minute (m/min). For rotational motion, the formula for converting revolutions per minute (RPM) into SFM is:

V = SFM = RPM x (πd)/12 = RPM x 0.262 x d

where for sleeve bearings d = ID and for thrust washers

d = mean diameter = (ID+OD)/2

For oscillating motion, cycles per minute (CPM) are converted into SFM using:

V = SFM = (4αc)/360 x (πd)/12 = 0.00291 x α x c x d

where α = amplitude of motion either side of mean position in degrees

c = frequency in cycles per minute

For linear or reciprocating motion, velocity is generally expressed in SFM or m/min.The maximum allowable surface velocity for LUBRON AQ bearings depends on the applied load and other operating and environmental variables. In general, surface velocity should not exceed 35 SFM for continuous operation.

PV Limit

PV is the product of bearing pressure (P) and surface velocity (V), and is used as a means of measuring bearing performance. Values for pressure and velocity must be considered individually, as well as their combined product. Temperature is the most important factor in determining a bearings PV limit. For most cases, the PV limit reflects the point where surface temperatures are at a maximum, but still stable. Therefore, anything affecting surface temperature - coefficient of friction, running clearance, hardness and surface finish of the mating material - will also affect the PV limit. Bearings which operate at lower PV limit will generally have longer service lives. LUBRON AQ bearings will perform best when the bearing assembly is designed for maximum heat dissipation and the recommended mating materials are used.

Type of Movement

The recommended PV limits listed in Table 1 are based on rotating motion and intermittent operation. For oscillating and reciprocating motion, or for continuous operation, up to 50% of the PV limit should be used, depending on the service life required.

LUBRON AQ bearings are especially effective for intermittent oscillating and reciprocating motion where conventional lubricants are inadequate. By providing a tough solid lubricant film over the sliding surface, LUBRON AQ bearings offer maximum resistance to wear and seizure under the harshest operating conditions.

SHAPES

LUBRON AQ bearings are available in many different configurations depending on the application, direction of load, and type of movement. Most common shapes are listed below.

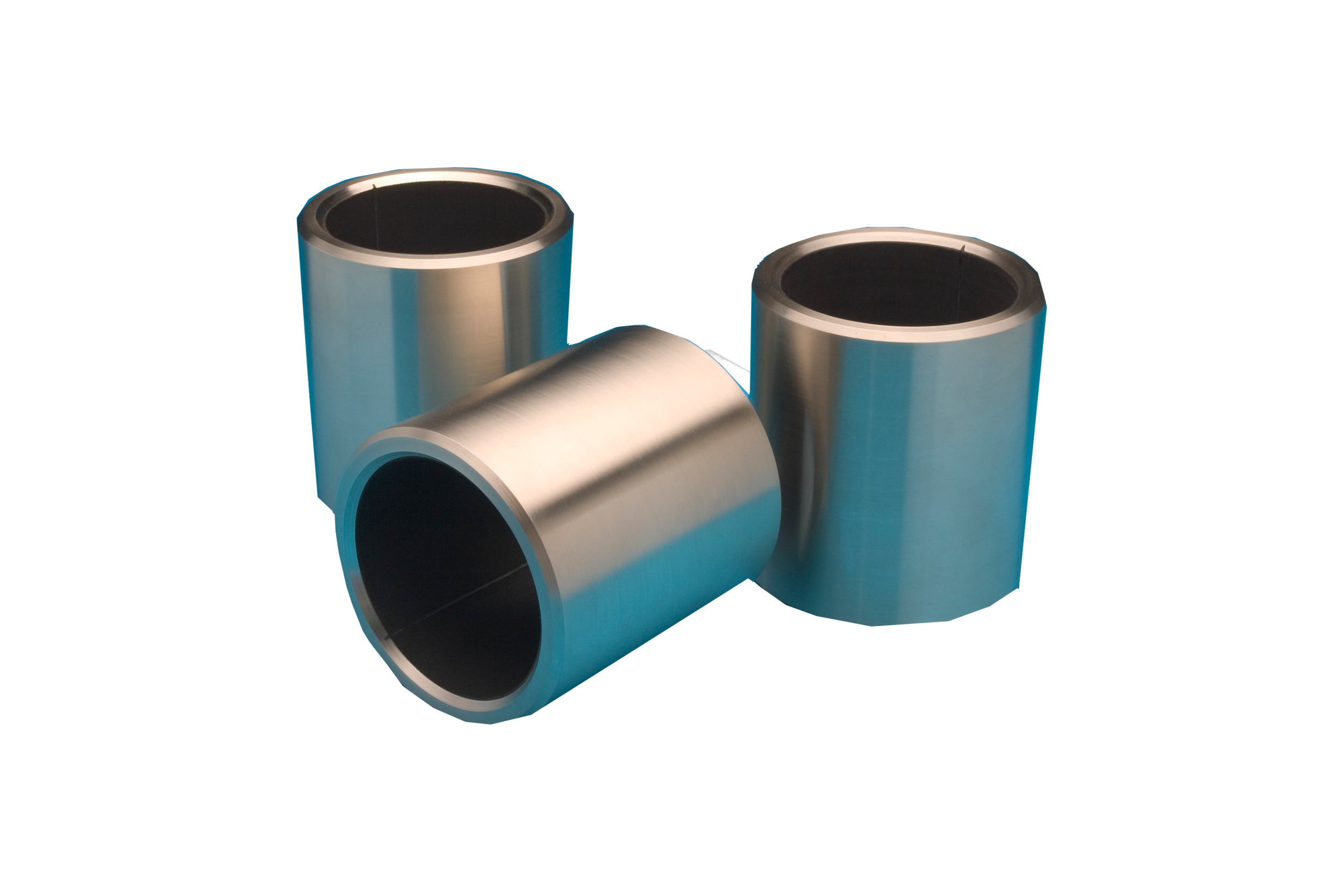

Bushings

One-piece sleeve bushings are used extensively to accommodate all types of rotary and linear motion. Sleeve or journal bushings are employed when the shaft load is essentially perpendicular to the axis of the shaft (radial loads). Either or both the inside or outside diameters of the bushing can be lubricated. Depending on the bearing size and application, the lubricating recesses may extend completely through the bearing wall or, for larger bushings or bushings subject to heavier loads, the lubricating recesses will only extend partially through the wall.

Where split housings or a need for disassembly and reassembly make split bushings advantageous, LUBRON AQ bearings are available either matched (split before final machining providing perfect 180° halves) or unmatched (split after final machining varying slightly from perfect 180° halves). Perfect halves are match-marked for proper assembly to assure maintenance of concentricity.

Washers

Washers are used to accommodate rotational end thrust when the shaft load is in the direction of the axis of the shaft. Used alone or in conjunction with sleeve bushings, LUBRON AQ washers can be lubricated on one or both sides.

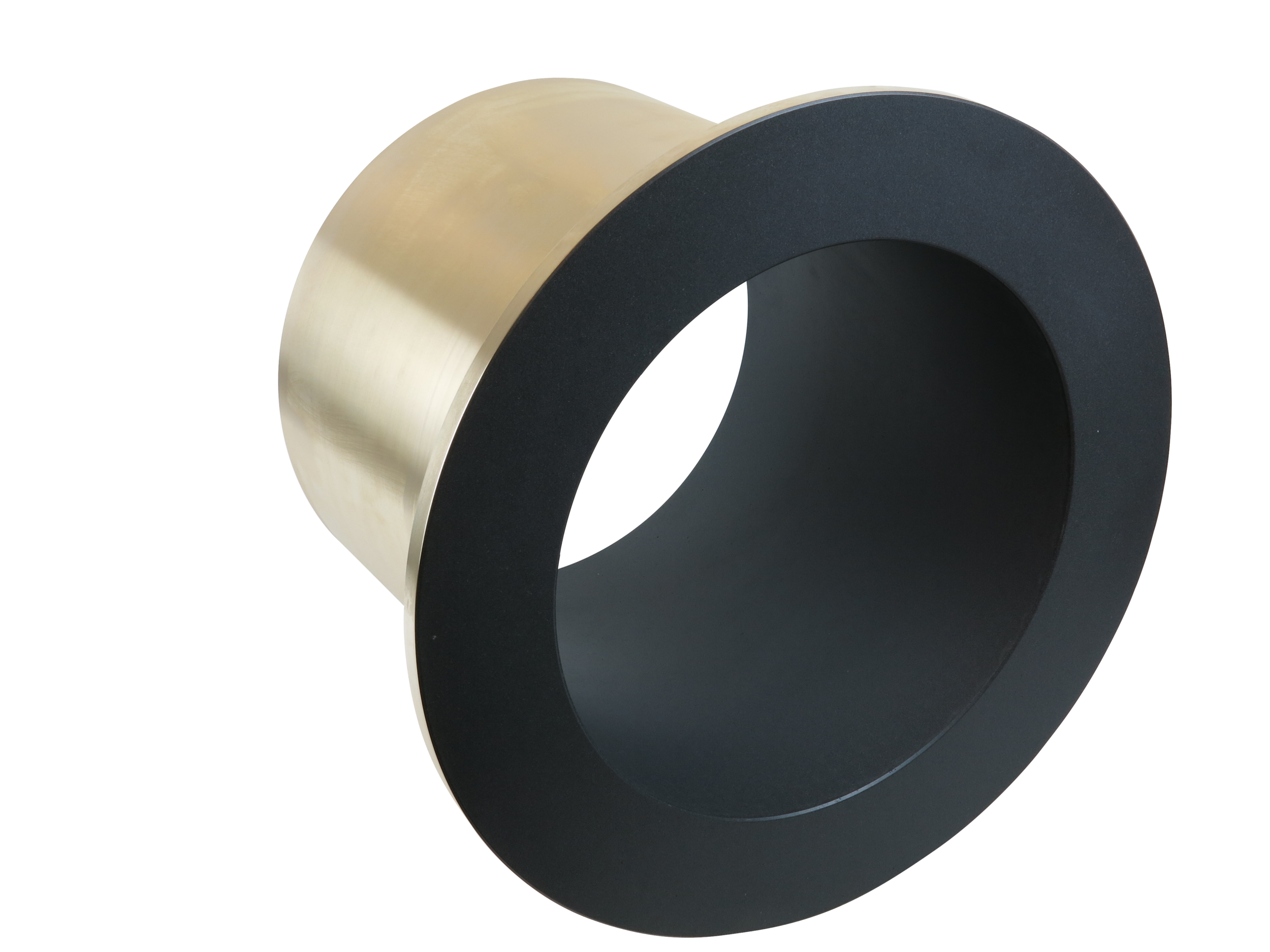

Flange Bushings

Flange bushings combine the features of sleeve bushings and washers into one unit. Available with flanges on one or both ends, flange bushings are used when the shaft load has both an axial and a perpendicular component. The flanges may be lubricated for thrust load applications, or provided without lubrication when required to function only as a spacer.

Spherical Bearings

Self-aligning spherical bearings are designed to accommodate radial loads and some misalignment. Misalignment may be caused by articulation, rotation or structural deflections under load. LUBRON AQ spherical bearing assemblies consist of an inner component (gimbal) with a cylindrical inside diameter for shaft rotation and a spherical convex outside diameter, and a two-piece outer component (race) with a mating spherical concave inside diameter and a cylindrical concave outside diameter for mounting in a housing. Either component can be lubricated. Stainless roller wheels are also available from Lubron Bearing Systems in combination with self-aligning spherical bearings.

Plates

Flat plates are frequently used to accommodate longitudinal and transverse movement under compressive loads. LUBRON AQ bearing plates are generally fastened with machine screws. Parallelism between the bearing plate and the mating plate should be within .001 inches per inch of width or length. Where edge loading caused by eccentric forces is present, self-aligning radial or spherical bearing plates should be considered.

SIZING

While many factors affect bearing design, the following data is applicable for most LUBRON AQ bearings. Available in both inch and metric sizes, LUBRON AQ bearings are supplied finished machined to meet the exacting requirements of each application.

Inside Diameter

The nominal inside diameter of a bushing is dependent on the shaft diameter. To obtain the lowest frictional resistance and power loss, the shaft strength and rigidity should be as high as practical to permit the smallest possible shaft diameter. When bushing sizes need to be increased to accommodate larger loads, increasing the bearing length rather than enlarging the bushing inside diameter is recommended. As the inside diameter is increased, there is a relatively larger running clearance which results in a proportionately smaller contact surface area. This reduction in contact area has the same effect as increasing the bearing load.

Outside Diameter

The outside diameter of a bushing is dependent on the required wall thickness and size of the housing bore. To determine the outside diameter, add twice the recommended wall thickness of the inside diameter of the bushing. The following Tables provide the recommended wall thickness for LUBRON AQ bushings. The minimum and maximum values shown in Tables 2 and 3 are suitable for most applications, and are based on the permissible shaft load, bushing diameter and yield strength of the bearing material. In general, lower strength alloys should require the maximum wall thickness, while higher strength alloys can utilize minimum wall thickness.

Length

Bearing length is usually determined by the amount of projected area necessary to accommodate the radial load, and can be calculated by dividing the shaft load by the desired bearing pressure times the inside diameter. In general, the length-to-diameter (L/D) ratio of a bushing should be between 1.0 and 2.0 for best performance. Shorter lengths may cause the bearings to become over-stressed, while longer lengths may induce edge loading. Bearings designed within the recommended L/D ratio will usually tolerate shaft misalignment and shock load without excessive wear.

Flange and Washer Thickness

The thickness for a bushing flange or thrust washer is generally the same as the corresponding wall thickness for a bushing listed in Tables 2 and 3.

Plate Thickness

Plate thickness should be consistent with the overall plate size. A minimum of one-half inch (12.7 mm) is recommended for most flat plates. A minimum thickness of one inch (25.4 mm) is desirable for radial and spherical plates where one or both sides are lubricated.

Running Clearance

Running or diametrical clearance, which is the amount the bushing inside diameter exceeds the shaft diameter after press fit closure allowance, is dependent on several factors including bearing load, speed, size, temperature, and type of application. Tables 2 and 3 provide recommended clearance limits for LUBRON AQ bushings prior to assembly for sizes ranging from 1 inch (30 mm) to 30 inches (765 mm). The clearance limits must be adjusted for any closure due to press fit by adding the maximum interference to the limits of clearance. These adjusted values will normally permit adequate running clearance after assembly for static to slow speeds and intermediate to heavy loads. LUBRON AQ bushings may require larger clearances for special conditions. For severe or special conditions, please consult a LUBRON engineer.

Tolerances

Machining tolerances for most LUBRON AQ bearings range from ±.001 to ±.002 inches (.025 to .050 mm) for inside diameters, and ±.0005 to ±.001 inches (.012 to .025 mm) for outside diameters. Surface finishes will generally not exceed 63 μ inch (1.6 μ m).

Mating Surfaces

LUBRON AQ bearings will operate against most metals, but best performance is achieved with the hardest possible mating surface. A minimum hardness of Rc 20 (BHN 228) is desirable, although softer materials will generally provided satisfactory performance. Smoother finishes are normally required for harder materials, higher loads, and higher surface speeds. For maximum wear resistance, mating materials should be machined and polished to a surface finish between 16 to 63 μ inch (0.4 to 1.6 μ m). Mating materials should be selected that will most effectively resist corrosion. Austenitic (Types 304 and 316) and precipitation-hardened (17-4 PH) stainless steels are commonly utilized in fresh and salt water mediums.

Carbon steel shafts can be refurbished using stainless steel sleeves, which are available from Lubron Bearing Systems. For larger journal sizes, Monel, Inconel, and stainless steel weld overlays are recommended.

Installation

LUBRON AQ bearings are supplied fully machined and ready for installation. Even though LUBRON AQ bearings are extremely durable, care must be taken to ensure that the lubricated bearing surfaces are not damaged before or during installation.

PRESS FIT

LUBRON AQ bearings are most often press fit into their housings. The bushing outside diameter is slightly larger than the housing bore, resulting in a press of interference fit. Press fitting will cause the inside diameter of the bushing to close-in, usually in direct ratio of the magnitude of the interference fit. This close-in must be compensated for in the bearing design to achieve the proper running clearance after press fit.

The sizes recommended in Tables 2 and 3 provide the proper interference fits for assembly. The bearings must be inserted squarely into the housings. Accurate alignment is particularly important for self-lubricating bearings. Misalignment over the length of the bearing or over the diameter of a thrust washer should not exceed .001 inches per inch. Chamfers are provided on the outside diameter of the bearing to facilitate proper alignment.

LUBRON AQ BRUSHINGS CLEARANCE & INTERFERENCE LIMITS

BEFORE PRESS FIT

TABLE 2 (inches)

| NOMINAL SIZE RANGE OVER TO | SHAFT DIA. (f7) | BEARING I.D. | LIMITS OF CLEARANCE | BEARING O.D.(r7) | HOUSING I.D. (H7) | LIMITS OF INTERFERENCE | RECOMMENDED WALL THICKNESS |

| 1.00-2.00 | -.001 -.002 | +.008 +.007 | .008 .010 |

+.003 +.002 | +.001 -.000 | .001 .003 |

.125 .375 |

| 2.00-3.00 | -.0010 -.0025 | +.0100 +.0095 | .0105 .0125 |

+.003 +.002 | +.001 -.000 | .001 .003 |

.250 .500 |

| 3.00-5.00 | -.001 -.0030 | +.0130 +.0115 | .013 .016 |

+.0035 +.0025 | +.0015 -.0000 | .0010 .0035 |

.375 .625 |

| 5.00-7.00 | -.0015 -.0030 | +.016 +.014 | .0155 .0190 |

+.0040 +.0025 | +.0015 -.0000 | .001 .004 |

.500 .750 |

| 7.00-10.00 | -.002 -.004 | +.021 +.017 | .019 .023 |

+.005 +.003 | +.002 -.000 | .001 .005 |

.625 .875 |

| 10.00-12.00 | -.0025 -.0045 | +.0215 +.0195 | .022 .026 |

+.0055 +.0035 | +.002 -.000 | .0015 .0055 |

.750 1.000 |

| 12.00-16.00 | -.003 -.005 | +.0245 +.0220 | .0250 .0295 |

+.0065 +.0045 | +.0025 -.0000 | .0020 .0065 |

.875 1.125 |

| 16.00-20.00 | -.0040 -.0065 | +.0275 +.0250 | .029 .034 |

+.0075 +.0050 | +.0025 -.0000 | .0025 .0075 |

1.000 1.250 |

| 20.00-30.00 | -.005 -.008 | +.033 +.028 | .033 .038 |

+.010 +.008 | +.003 -.000 | .005 .010 |

1.000 1.500 |

TABLE 3 (mm)

| NOMINAL SIZE RANGE OVER TO | SHAFT DIA. (f7) | BEARING I.D. | LIMITS OF CLEARANCE | BEARING O.D. (r7) | HOUSING I.D. (H7) | LIMITS OF INTERFERENCE | RECOMMENDED WALL THICKNESS |

| 30-50 | -.025 -.051 | +.209 +.185 | .210 .260 |

+.076 +.051 | +.025 -.000 | .025 .076 |

3.2 9.5 |

| 50-80 | -.025 -.063 |

+.264 +.242 |

.267 .327 |

+.076 +.051 | +.025 -.000 | .025 .076 |

6.3 12.7 |

| 80-120 | -.038 -.076 | +.326 +.294 | .332 .402 |

+.089 +.063 | +.038 -.000 | .025 .089 |

9.5 15.9 |

| 120-180 | -.038 -.076 | +.404 +.362 | .400 .480 |

+.102 +.063 | +.038 -.000 | .025 .102 |

12.7 19.1 |

| 180-250 | -.051 -.102 | +.472 +.431 | .482 .574 |

+.127 +.076 | +.051 -.000 | .025 .127 |

15.9 22.2 |

| 250-315 | -.063 -.114 | +.551 +.498 | .561 .665 |

+.140 +.089 | +.051 -.000 | .038 .140 |

19.1 25.4 |

| 315-400 | -.076 -.127 | +.629 +.566 | .642 .756 |

+.165 +.114 | +.063 -.000 | .051 .165 |

22.2 28.6 |

| 400-500 | -.102 -.165 | +.696 +.633 | .735 .861 | +.190 +.127 | +.063 -.000 | .063 .190 |

25.4 31.8 |

| 500-765 | -.127 -.203 |

+.763 +.701 | .828 .966 |

+.254 +.203 | +.076 -.000 | .127 .254 |

25.4 38.1 |

Shouldered arbor plugs should be used to install smaller bearings. For larger sizes, LUBRON AQ bearings can be refrigerated or packed in dry ice prior to installation. Immersion in liquid nitrogen is generally permitted provided the temperature of the bearing does not fall below -112 º F (-80º C). LUBRON AQ bearings can also be retained in the housings with countersunk set screws, dowel pins, or keyways.

LUBRON AQ bearings should be wiped clean and free of all debris prior to installation of the shafts. Proper housing design and sealing of the bearing will prevent the ingress of foreign debris during operation. Application of a supplementary non-soluble lubricant during assembly will permit easier installation and provide better initial performance. The shaft ends should be burr-free and have a minimum of .060 inch (1.5 mm) radius or 15° chamfer. LUBRON AQ bearing inside diameters are normally furnished with 30° chamfers. Unlike most other self-lubricating bearings, LUBRON AQ bearings can be machined after assembly to control running clearance or correct minor misalignment. When circumstances necessitate field machining the lubricated bearing surface, consult a LUBRON engineer for specific recommendations.

Supplementary Lubrication

LUBRON AQ bearings are frequently used where oil and grease lubrication are impractical. However, special operating conditions my exist that require the use of a supplementary lubricant. In such cases, LUBRON AQ bearings can be furnished with one of several groove patterns to accommodate most types of loading, movement and lubricating requirements. Typical patterns include straight, circular, figure 8, and oval grooves. Grooves may be specified in any width and depth, and can run out one or both ends. Seal grooves may also be added for applications subject to ingress of foreign debris.

Selection of a suitable oil or grease is dependent on the operating conditions, environment, convenience and cost. While most oils and greases are compatible with LUBRON AQ bearings, calcium and lithium multi-purpose Grade 2 greases without MoS2 additives are generally more sutiable.

MANUFACTURING CAPABILITIES

Our manufacturing facilities are modern, flexible, and complete, capable of complex tasks with precise accuracy. Our diverse design and manufacturing skills combine to assure consistent quality and reliable performance from small bushings to large bearing assemblies.

QUALITY ASSURANCE

Every LUBRON bearing manufactured by Lubron Bearing Systems is guaranteed to meet or exceed the quality requirements for each job. From procurement and fabrication to final inspection, every phase of manufacturing is monitored by our quality control personnel. Every step is planned, performed, checked, and certified in writing. All LUBRON bearings are manufactured and inspected in strict accordance with the requirements of ISO 9002. Non-destructive testing, including radiograph, ultrasonic, hydrostatic, magnetic particle, and liquid penetrate examination, are performed to comply with the specifications of ASTM by certified independent testing laboratories.

ENGINEERING & TESTING

Lubron engineers have extensive product knowledge and experience in metallurgical, mechanical and structural disciplines. We offer our customers a variety of engineering services, from selection of bearing alloys and mating materials, to prototype and full size production testing to simulate load, movement, temperature, and other environmental conditions present during the actual operation of LUBRON bearings. Coefficient of friction and wear testing is performed in-house or by independent testing laboratories. Bearing design, AutoCAD drawing preparation, testing, consulting, and on-site engineering services are available upon request.

STANDARD SPECIFICATION FOR LUBRON AQ100

SELF-LUBRICATING BUSHINGS

The following specification is recommended for heavy duty water control applications. Specifications for other applications and bearing configurations are available upon request.

Self-lubricating bronze bushings shall be equal to "LUBRON AQ100" as manufactured by Lubron Bearing Systems, Huntington Beach, California, USA. The bushings shall be composed of supporting metal and a solid lubricant suitable for underwater application. The bushings shall be one-piece construction with a self-lubricating bearing surface on the inside diameter.

The supporting metal shall be high strength manganese bronze, Copper Alloy UNS No. C86300, manufactured in strict accordance with ASTM B22 Alloy C86300, ASTM B271-C86300, ASTM B505-C86300 or ASTM B584-C86300.

Circular recesses for containment of the lubricant shall be machined or cast perpendicular to the bearing surface, be at least .25 inches (6.4 mm) deep or extend completely through the supporting metal, and be arranged in a uniform, overlapping geometric pattern in the direction of the rotating motion. The pattern of recesses shall have a net cross-sectional area that is not less than 30% of the total area of the surface and shall normally extend to within approximately .125 inches (3.2 mm) of the chamfers at each end of the bushings.

The solid lubricant shall be a dense combination of solids and binders having non-deteriorating characteristics as well as lubricating qualities and shall be capable of withstanding the effects of long-term atmospheric exposure and submersion in flowing water. The lubricant shall not contain graphite, molybdenum disulfide, or any other ingredients that tend to promote electrolytic or chemical action. The use of shellac, tars, resins, solvents, or other non-lubricating binder materials is not acceptable. The self-lubricating compound shall be integrally molded and compressed into recesses provided for containment, with an additional coating up to .040 inches (1 mm) applied to 100% of the bearing surface area. The lubricant shall be free from detrimental pits, pinholes, and other imperfections that will impair the design load capacity. The lubricant shall have a Type D Durometer hardness of at least 80 when tested in accordance with ASTM D2240.

The bushings shall not be damaged, scraped, or machined on the lubricating surface after manufacture. The surface finish of the bushing and the lubricant film shall not exceed 63 microinches (1.6 micrometers) as measured in accordance with ANSI Standard B46.1. The bearing manufacturer shall recommend the housing and shaft tolerances to assure proper interference fit and running clearance of the bushings. The bushings shall have a design load capacity of at least 8 ksi (55 MPa) of projected bearing area at surface speeds not exceeding 10 fpm (.05 m/s). The static and dynamic coefficients of friction shall not exceed 0.10 when subjected to loads up to 8 ksi.

LUBRON Self-Lubricating Bearings for Hydro Applications

LUBRON AQ

LUBRON AQ bearings are constructed of high strength bronze alloys permanently embedded with PTFE solid lubricants, and are unequaled for toughness and durability. Specified and approved by engineering design firms and water power authorities worldwide, LUBRON AQ bearings are the proven choice for hydro pump-turbine and dam gate applications.

LUBRON TF

LUBRON TF bearings are constructed of woven PTFE fabric liners permanently bonded and mechanically locked to rigid bronze or stainless steel backings. Capable of very low friction and high wear resistance, LUBRON TF bearings offer exceptional performance for hydro turbine wicket gate, control linkage, butterfly valve and dam gate applications.